[1] Rice Cake Machines

[2] Automatic Feeder / Stacker

[3] Horizontal Packaging Machine

[4] Continuous Puffing Machines

[5] Extruders

Links:

www.gmgmachinery.com

cerealpuffing.com

|

[1] Single and Multiple Moulds

Rice Cake Machines

Small production

GMG M1-M2 |

Medium production

GMG M4 |

Standard production

GMG M6 |

Big production

GMG M9-M12 |

|

|

|

|

1 mould 90 mm diam.

Capacity: 360 cakes/h

---

2 moulds 90 mm diam.

Capacity: 720 cakes/h |

4 moulds 90 mm diam.

Capacity: 1440 cakes/h |

6 moulds 90 mm diam.

Capacity: 2160 cakes/h |

9 or 12 moulds 90 mm diam.

Capacity: from 3200 cakes/h |

6 moulds 45 mm diam.

Capacity: 2160 cakes/h |

3 moulds 100 mm diam.

Capacity: 1080 cakes/h |

28 moulds 45 mm diam.

Capacity: 8000 cakes/h |

6 moulds 100 mm diam.

Capacity: 2160 cakes/h |

ask for

GMG M1 price

GMG M2 price

|

ask for

GMG M4 price |

ask for

GMG M6 price |

ask for

GMG M9 price

GMG M12 price

|

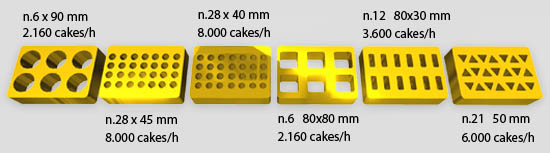

Example of moulds for GMG M6:

|

Raw material that can be used:

|

Cereal grains or pellets from cereals: rice, corn, wheat, and also rye, barley, millet, buckwheat, amaranth, quinoa, etc...

|

Operation: |

Raw rice or rice mixed with other cereals are put in the hopper on top of the machine. Starting from this point the machine is automatic and cake production begins. If necessary rice is humidified beforehand, by adding little quantity of water. |

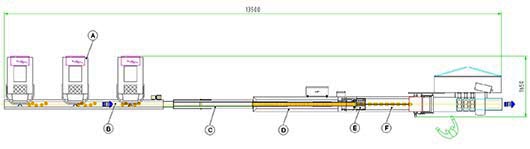

| Complete Rice Cake production lines: |

We are able to supply-install-servicing full integrated rice cake production lines including:

- Cereal Mixer with Humidification System

- Automatic System to convey the raw material to the Hoppers on top of the machines

- Automatic Stacker (made by vibrating channels that do not damage or break the rice cakes) and Feeding System to the Packaging Machine

- Packaging Machine

- Spraying and Drying Equipment for cake coating/aromatization

- Chocolate Enrober

ask for

GMG Rice Cake Production Line price

|

top |